- HOME

- NEWS

- White Paper

- Boncha Bio Optimizes Nutrient Delivery with Innovative Candyceutical Technology: A Technical Dive into Next-Gen Dosage Forms

Boncha Bio Optimizes Nutrient Delivery with Innovative Candyceutical Technology: A Technical Dive into Next-Gen Dosage Forms

Part 1: Introduction and Background

In the dynamic landscape of the health food industry, where innovation is key to success, Boncha Bio has introduced a next-generation advancement: the candyceutical.

'Candyceutical' is a revolutionary, all-in-one solution in the health supplements industry. It merges the concept of 'candy' with nutraceutical, featuring candy-textured soft gel specifically designed to contain high-dose active ingredient fillings. These capsules not only offer an easy-to-chew gummy texture but also boast enhanced effectiveness, thanks to their high bioactivity and absorption rates.

But what exactly is a "Candyceutical," and how did Boncha Bio, a biotech company based in Taipei, Taiwan, emerge as a beacon of innovation for the industry’s long-standing challenges in nutrient bioactivity and user compliance? This white paper unfolds the story behind this pioneering leap, spotlighting Boncha Bio's journey towards an innovative discovery in health solutions.

1000_500.png)

Challenges in Conventional Supplement Forms

The range of dosage forms in health supplements is vast and varied, yet it is common for consumers to find themselves dissatisfied with the results. Why do some products fall short of expectations, even when used strictly according to supplement guidelines? How can we alleviate the pill-fatigue experience, a common issue associated with taking medication and supplements? Often, these problems are rooted in the delivery system of the supplements themselves. The industry faces challenges such as reduced bioactivity in gummies, along with the inconvenience and discomfort of ingesting soft gels, capsules, and tablets.

Driven by the goal to enhance both efficacy and user experience, Boncha Bio embarked on a mission to address these fundamental challenges.

The Genesis of Candyceuticals

Founded in 2015, Boncha Bio initially focused on producing traditional supplement forms such as candies, soft gels, and gummies. However, the team soon recognized the need for a more innovative and user-friendly delivery system within the supplement industry. This realization set them on a path of exploration, leading to experiments with various prototypes, each with unique production and stability challenges.

Their ventures into developing chocolate capsules, gum bases, and gummies with integrated fillings gradually brought them closer to their goal. Each prototype, however, faced significant production hurdles. The gummies required high temperatures during processing, chocolate formulations were limited in flavor options, restricting the use to a limited range of active ingredients, and fillings in both forms tended to leak. These challenges propelled Boncha Bio to continue refining their approach, ultimately leading them to the innovative development of Candyceuticals.

1100_550.png)

Developing the Candyceutical: A Leap in Nutraceutical Innovation

The game-changing moment for Boncha Bio came after rigorous testing of over 400 parameters and formulations. This intensive effort led to a significant breakthrough: the creation of the“candyceutical,”a palatable, chewable candy capsule enriched with nutrients and innovatively designed to prevent leakage. This next-generation dosage form effectively combines the enjoyment of a candy capsule shell with a filling packed with active ingredients. It symbolizes a perfect fusion of taste and health, showcasing Boncha Bio's dedication to enhancing the supplement experience.

In the following section, we will delve into the technical advancements and unique features of the candyceutical, highlighting how this innovative product is set to revolutionize the supplement industry.

Part 2: Candyceutical Developmental Breakthroughs and Technical Innovations

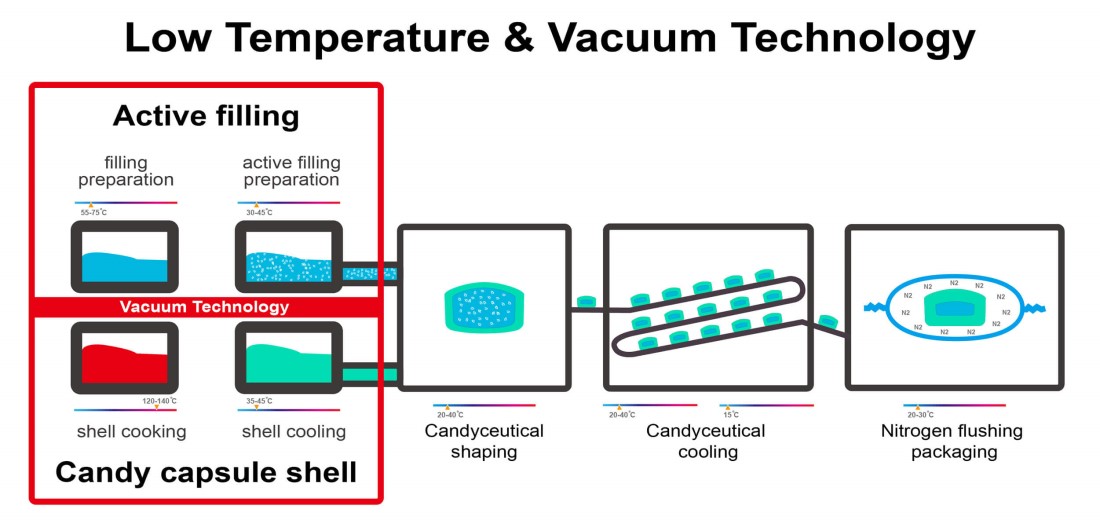

Given that 80% of active ingredients and nutrients are sensitive to heat, oxygen, and pressure, a crucial question arises: how can these vulnerabilities be effectively tackled? Boncha Bio responded to this challenge by implementing a proprietary production process specifically designed to maintain higher bioactivity in candyceuticals. This approach not only preserves the integrity of sensitive ingredients but also maximizes their efficacy, paving the way for a new era in supplement formulation and delivery.

1. Lower Temperature Manufacturing Process: Preserving Bioacativity

- Manufacturing Challenge:

Traditionally, gummies are produced at temperatures ranging from 70°C / 158°F to 110°C / 230°F, necessary for achieving the right fluidity and maintaining minimal water content for effectively mixing active ingredients and molding. Insufficient fluidity leads to a jellified texture, akin to cold honey, complicating the mixing and molding process. However, these high temperatures adversely affect heat-sensitive ingredients like omega-3, probiotics, antioxidants, and certain vitamins, often leading to a significant loss in bioactivity. For example, most probiotics are completely destroyed in this high-temperature process.

- Innovative Solution:

Candyceuticals are produced at substantially lower temperatures, around 40°C +/- 10% / 104°F +/- 10%. This is made possible by machinery adjustments and specialized formulations. The unique, non-jelly-like form of candyceuticals eliminates the need for high temperatures during mixing and molding. Furthermore, candyceuticals utilize low compression shaping, not requiring high temperatures and fluidity. This cooler production environment is beneficial for preserving heat-sensitive ingredients such as probiotics (like Bifidobacterium or Lactobacillus), omega-3 (like fish oil, algae oil- vegan DHA), and vitamins. For instance, 95% of probiotic CFU count is maintained post-production, as verified by third-party accredited laboratory tests.

Explore the Fish Oil and Algae Oil Application

2. Mitigating Cross Contamination Risk & Ensuring Dose Consistency

- Drying Challenge:

Gummies require a specific water content to remain in a liquid state for molding. To achieve better gelatinization, reducing water content after molding is essential. Gummies typically undergo a drying process for several days:

- Starch Molds:

Often, special starch molds are used to absorb water from the gummies. However, this can lead to leaching of active ingredients into the molds, consequently reducing the dosage in the gummies and potentially risking mold contamination in subsequent production batches. Cleaning these starch molds is challenging and may render the starch unusable. Moreover, some starch may be reused to cut costs, but this risks cross-contamination if the molds are not thoroughly cleaned. As a result, some manufacturers resort to overdosing, which does not guarantee consistent dosage across each gummy.

- Silicone Molds:

While silicone molds prevent the loss of active ingredients and cross-contamination and are not involved in the drying process, they require a specific gummy formula for unmolding before drying, unlike starch molds. This requirement leads to a poorer gummy texture, which significantly limits product possibilities. Boncha Bio considered the use of silicone molds but ultimately found the limitations in the formulas too prohibitive.

- Starch Molds:

- Innovation Solution:

The candyceutical manufacturing process eliminates the need for traditional molding and drying. This is achieved through the use of low compression at low temperatures to achieve the right shape. Consequently, the active ingredients remain intact within the candyceutical, effectively preventing any risk of cross-contamination.

3. Vacuum Filling Technology: Preserving Ingredient Stability

- Challenge Addressed:

A significant issue in the manufacturing of soft gel products is the exposure to oxygen during the shaping process, which combines the filling with the soft gel's outer shell. Since this process cannot be conducted under vacuum conditions, oxygen from the air, which constitutes about 20% of its composition, not only gets entrapped within the soft gel but also extensively contacts the active ingredients throughout the prolonged shaping process, consequently triggering preliminary oxidation reactions. Oxygen naturally reacts with many active ingredients, leading to their inactivation. Although soft gels and their formulas are often reinforced with antioxidants, the quantities are generally too minimal to be fully effective, resulting in the gradual degradation of active ingredients over time.

- Technical Advancements:

Boncha Bio has implemented advanced and proprietary vacuum technology in the manufacturing and shaping of candyceuticals. This innovative process not only ensures the product's purity but also significantly diminishes the risk of oxidation. The vacuum machinery employed is finely calibrated to maintain oxygen levels below 1% in a substantially reduced pressure environment, specifically under 0.03 atmospheres. The remarkably low TOTOX values in Omega-3 product testing reports reflect this precise control of the atmosphere. Furthermore, the enhanced preservation of omega-3 in candyceuticals validates the efficacy of this advanced manufacturing technique.

4. Nitrogen-Infused Packaging: Enhanced Product Stability and Hygiene

- Existing Challenge:

Traditional packaging methods, such as bottles, offer excellent protection when sealed but have their drawbacks. These bottles typically contain air instead of nitrogen. Supplements in soft gels and gummies are not airtight, which fails to prevent oxygen infiltration into the shell, candy base, and even central filling. Consequently, products like omega-3 soft gels start oxidizing even before the bottle is opened, reducing their effectiveness. This issue is often reflected in consumer feedback, where complaints about fishy odors in fish oil soft gels are common. Upon opening these bottles, the exposure to oxygen and humidity accelerates the degradation of active ingredients, significantly shortening the product's shelf life. Moreover, the impracticality of carrying a whole bottle and the risks of individual gummies or soft gels melting, leaking, or becoming contaminated in transit add to consumer inconvenience and product wastage.

- Innovative Solution:

Boncha Bio has tackled these challenges by adopting a cutting-edge approach - individually sealing each candyceutical in an aluminum foil sachet infused with nitrogen. This nitrogen-infused environment maintains the oxygen concentration below 1%, drastically reducing the risk of oxidation during storage. This is a stark contrast to traditional soft gel packaging, where products are exposed to air with around 20% oxygen concentration. Moreover, sachet packaging offers robust protection against humidity, and the absence of a drying process in this method significantly minimizes oxygen exposure. This is crucial for preserving the integrity of unsaturated fatty acids and preventing rancidity. The effectiveness of this technology is corroborated by low TOTOX values and a high preservation rate of omega-3, as evidenced in accelerated stability tests. Additionally, 20-month real-time stability studies conducted in Zone IVb (ICH guidelines for stability studies), characterized by high temperature and humidity, have demonstrated the substantial benefits of this packaging innovation in maintaining consistent low oxygen levels inside the sachets.

Importantly, the individual sachets offer convenient portability, seamlessly fitting into an on-the-go lifestyle, whether in a purse or pocket, while negating contamination risks. One of the most valued aspects of candyceuticals is the hygiene of individually wrapped products, ensuring protection from external atmospheric elements, even in environments like subways or offices where exposure to bacteria and viruses is common.

5. Enhanced Coating of Actives in the Central Filling

- Innovative Solution:

The central filling of candyceuticals contains active nutrients, such as omega-3 from fish oil or algae oil (vegan DHA) and other actives, encapsulated within a protective layer of saturated fatty acids, like palmitic oil. This strategic coating layer effectively shields these actives from stomach acids, thereby enhancing the product's stability by both masking the unpleasant odors and improving the bioavailability of the active ingredients. This saturated fatty acid coating enables the combination of otherwise incompatible ingredients in a single health supplement formula, making it feasible to create beneficial blends like Omega-3 and Iron, which are ideal for pregnant women. In the intestinal environment, this fatty acid layer is naturally diluted by pancreatic juices and enzymes, including lipase PNLIP and PTL, effectively preparing the active ingredient for optimal absorption. This critical coating step is implemented during the low-temperature production process, maintained below 40°C, and under vacuum.

- Research Insight:

The selection of naturally sourced saturated fatty acids is specifically designed to resist gastric acids while being susceptible to pancreatic enzymes. This leads to a pre-emulsified state of the active ingredient, optimizing its delivery. This method, based on fundamental biochemistry and natural processes, ensures that a higher concentration of active ingredients reaches the intestine, thereby enhancing absorption. The technique employed here is akin to that used in liposome creation, demonstrating a commitment to innovative, science-based approaches in nutrient delivery.

Part 3: Consumer-Centric Innovations and Market Approval

Pectin-Based Vegan Options: Designing for Dietary Diversity

Responding to the increasing preference for vegetarian and vegan supplements, candyceuticals are formulated with vegetable oils and dietary fibers, enabling them to be easily adapted to 100% vegan, halal, and kosher standards. This approach caters to a wide range of dietary preferences, tapping into a significant segment of the growing health-conscious market.

Current market analysis estimates the vegan market's value to be approximately USD 16 billion as of 2022, and it is projected to expand at a compound annual growth rate (CAGR) of over 10% from 2023 to 2030. This growth reflects a global shift towards plant-based products, underscoring the importance of developing supplements that align with these evolving consumer preferences.

Deep Insights into Vegan-Friendly DHA Options.

Flavor-Masking Technique: Enhancing User Experience

A key advantage of candyceuticals lies in their palatability and ease of consumption. Traditional soft gels, while offering high doses of ingredients, often lack in flavor and texture and can be hard to swallow. In contrast, gummies, though tasty, expose active ingredients to harsh high-temperature production, potentially compromising their efficacy. Candyceuticals, however, offer a no-compromised solution: they are delicious, easy to chew and swallow, and allow for customized flavor enhancement and odor masking. Importantly, they maintain full efficacy of active ingredients, presenting an ideal solution without any trade-offs. The manufacturing process of candyceuticals enables adjustments in flavor, color, and chewability texture, greatly boosting consumer appeal.

Positive Market Reception and Consumer Satisfaction

Boncha Bio's innovative approach has already elevated the market position of numerous health supplement companies globally. Candyceuticals have received exceptional consumer response. Analysis of data from various online shopping platforms shows that more than 90% of customers express satisfaction with the product. One customer remarked, "It's both convenient and tasty, making it easy for me to remember my daily DHA intake," thus highlighting the product's appeal in terms of taste, convenience, and hygiene. Such favorable reception stands as a clear testament to the product's innovative design and effectiveness.

For more customer feedback, check out here.

Part 4: Concluding Insights and Future Outlook

Revolutionizing Supplement Consumption

Boncha Bio's candyceuticals represent a paradigm shift and mark a significant evolution in supplement manufacturing and consumption. They are particularly beneficial for those who find it difficult to swallow soft gels and align with the growing popularity of gummies. Candyceuticals effectively overcome the production challenges typically associated with standard gummies, offering an upgraded alternative.

Impacting Health Outcomes

The innovative design and technological superiority of candyceuticals are not solely about consumer appeal. They play a critical role in enhancing health outcomes. For example, omega-3 fatty acids, known for their comprehensive health benefits, often come with challenges such as unpleasant fishy odors, fishy burps, and aftertastes, leading to reduced consumer adherence. The improved palatability and user experience lead to better compliance, ensuring that consumers fully benefit from the nutritional advantages of the supplements.

Collaboration and Innovation

Boncha Bio is committed to expanding its reach and impact through collaboration and innovation. The factory adheres to the highest standards, being GMP, ISO, HACCP, and FDA registered, and employs rigorous 3rd party testing to ensure product quality and safety. Boncha Bio invites industry leaders and health brands to explore partnership opportunities and leverage the unique advantages of candyceuticals. With an advanced and proprietary manufacturing facility and adherence to the highest quality standards, Boncha Bio is poised to be a leader in the future of health supplements.

For More Information

To gain deeper insights into Boncha Bio's advanced techniques in Omega-3 product integration and explore potential partnerships, visit the Boncha Bio's Omega-3 Products Page – where health meets taste and technology.